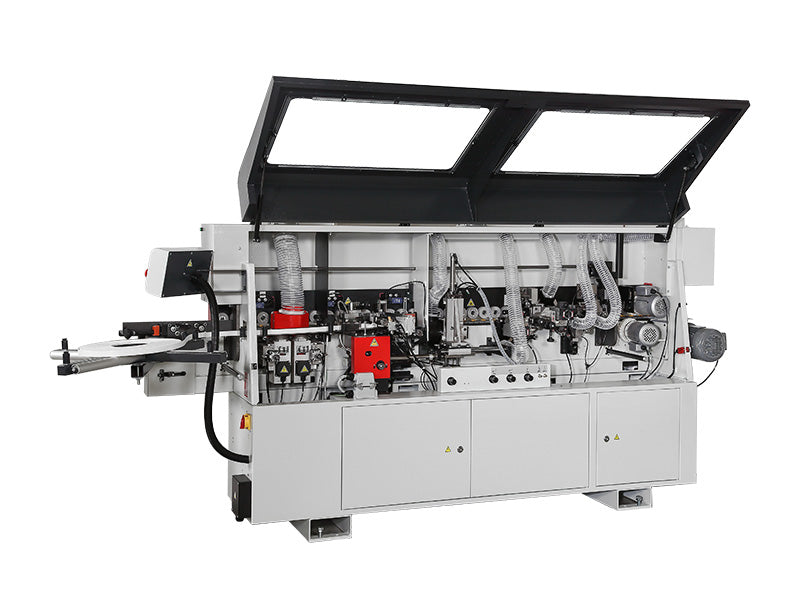

Cantek MX350 Automatic Edgebander

The Cantek MX350 Automatic Edgebander is a compact edgebander capable of applying up to 3mm thick edge tape on cabinet parts and more. The counter rotating pre-milling cutters ensure optimum panel edge quality and squareness which result in a less visible glue joint. It comes equipped with high frequency motors on both the end trim and top & bottom trim. In addition it is equipped with PVC radius scraping and buffing units. User friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm. It’s compact design and affordable price point make it the ideal edge banding solution for the small cabinet shop who requires pre-milling.

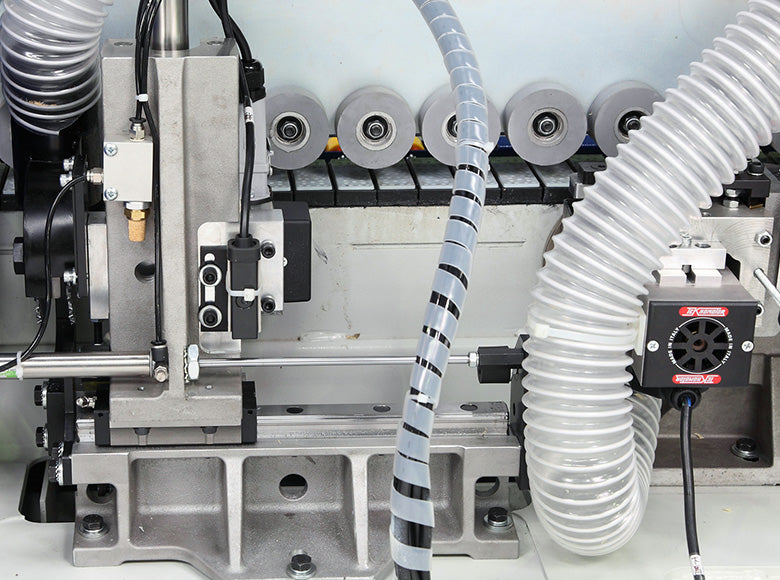

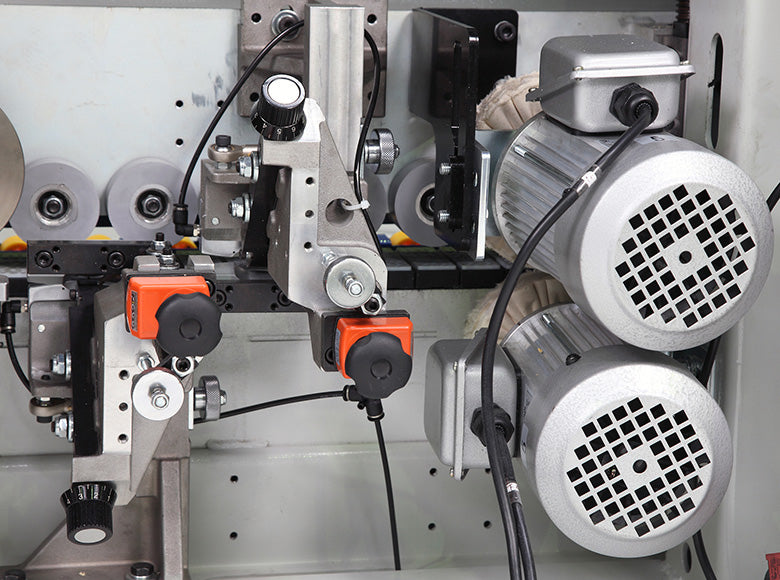

PREMILLING UNIT

High-frequency pre-milling units can remove up to 3mm and is designed to provide an ideal edge for applying edge tape by cleaning up poorly cut panels

(2) counter-rotating diamond cutterheads for optimum results and longevity

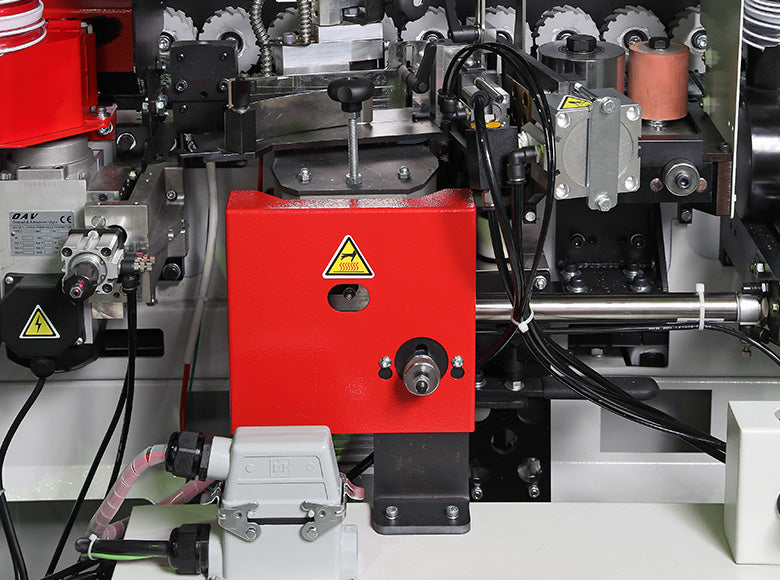

END TRIM

High frequency 12000 RPM end trimming unit, with Ø100mm (4") TC-Saw blades

TOP AND BOTTOM TRIM

High frequency 12000 RPM top & bottom trimmers with insert knife cutters for radius trimming & bevel trimming

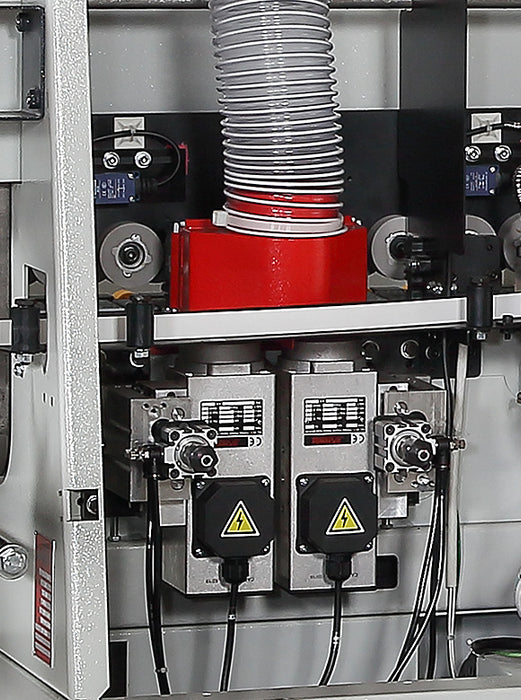

RADIUS SCRAPING

Radius scraper with 2mm radius

BUFFING

3000 RPM top & bottom buffing units to polish the machined edge

Key Advantages

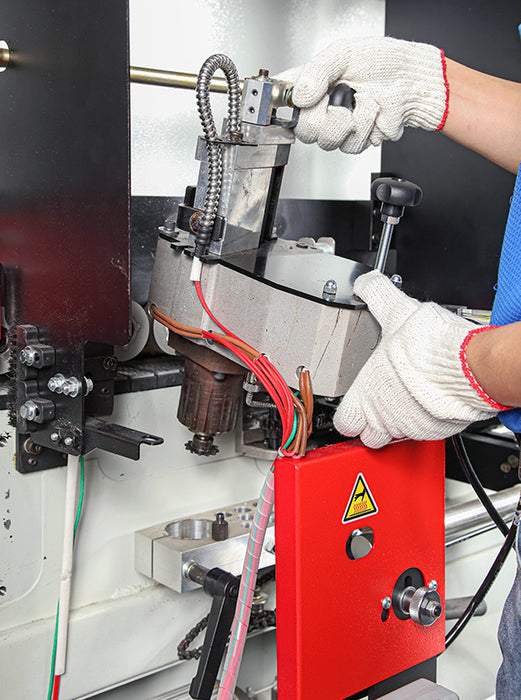

• Teflon coated Quick Change glue pot can be removed and exchanged in only minutes. Comes with (1) quick change pot and others can be acquired for running different color glues.

• Automatic edge feeding with a thickness capacity of 0.4–3 mm, strip material can be hand-fed

• Conveyor chain feed system for reliable results

• Heated infeed fence for pre-heating the panel for optimum glue penetration

• PLC control system with LED display and keypad

• Workpiece is fed by chain

• Edge coil support plate: Ø 800mm (31 ½"), for PVC/ABS

• Spring-loaded pressure unit with (2) pressure rollers

• Heavy-duty pressure beam with extendable workpiece support

Specifications

| Inch | Metric | |

|---|---|---|

| Feeding speed | 29FPM | 9 m/second |

| Panel thickness | 0.315"~1.77" | 8~45 mm |

| Max. pre-milling thickness | 1.77" | 45mm |

| Edge thickness | 0.0158"~0.118" | 0.4~3 mm |

| Min. panel width | 4" | 100mm |

| Min. panel length | 6.7" | 170mm |

| Working table height | 33.5" | 850mm |

| Dust collection outlet | Ø 5" x 3 | Ø 127 mm x 3 |

| Total connected power | 10 HP | 7.5 kW |

| Machine dimensions (LxWxH) | 147" x 52" x 54" | 3700 x 1310 x 1380mm |

| Machine weight | 1452 lbs | 660 kgs |

| Shipping dimensions (LxWxH) | 91" x 29" x 54" | 2290 x 720 x 1370mm |

| Shipping weight | 1558 lbs | 708 kgs |

| Electrical requirement | 230/3/60: 40 amps | |