SELEXX Series CNC Machine

SELEXX Series CNC Machine is backordered and will ship as soon as it is back in stock.

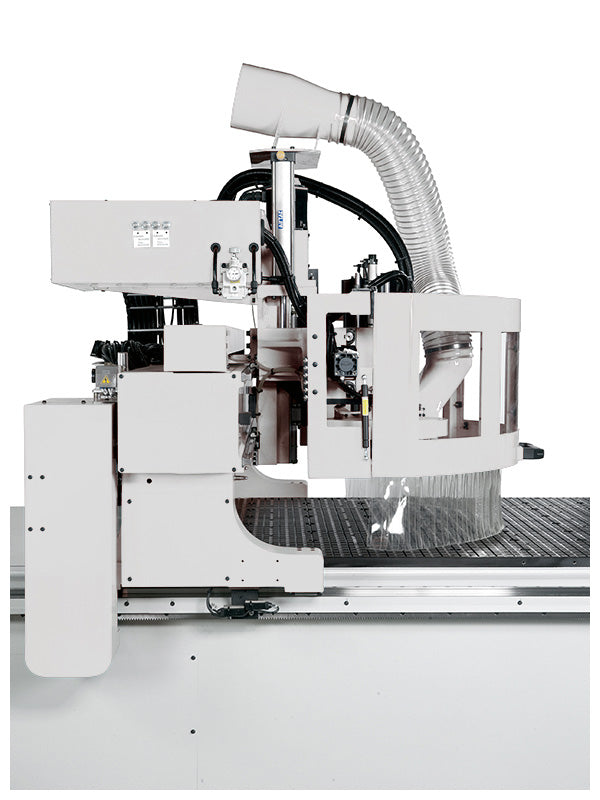

Introducing the Anderson SELEXX Plus

An industrial-grade CNC machine that perfectly balances high performance and value, the Anderson Selexx Plus is engineered for durability and precision. It's a testament to our commitment to providing robust, reliable solutions that enhance productivity without compromising on quality. The Selexx Plus is not just a machine, but a strategic investment in your business's future.

High Performance Meets Value

Designed for users with demanding needs, the Selexx Plus is the ideal CNC solution for those who don't require the extreme speeds of our larger Stratos and Exxact Models, but still need a reliable, high-performance machine.

Key Features

• Variety of Table Sizes: Choose the size that fits your needs.

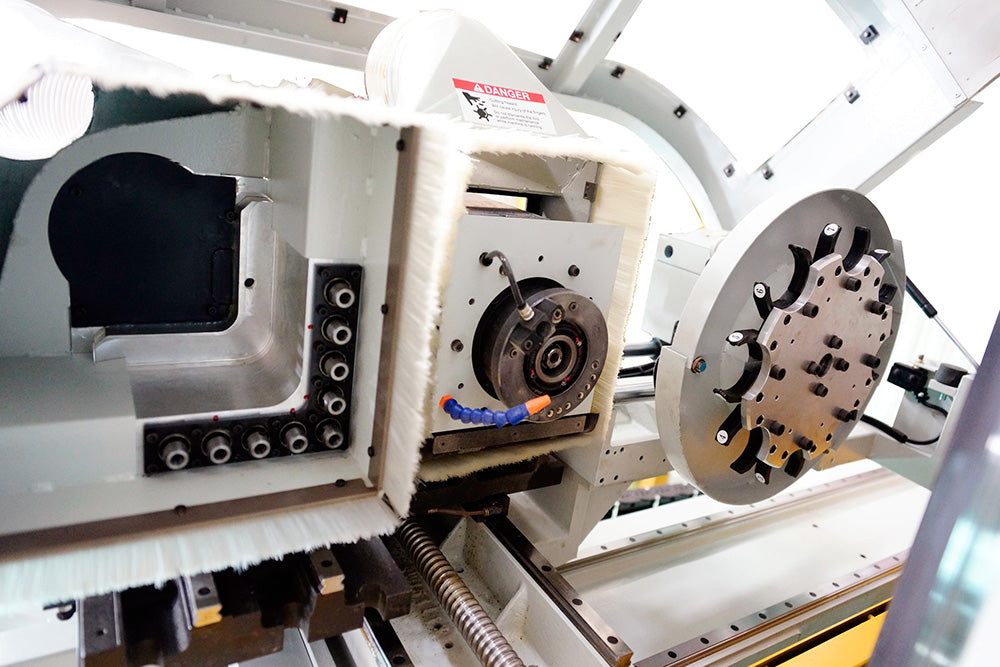

• Aggregate Capability and Ride-Along Tool Changer: Eliminates wear caused by up to 500 unnecessary rapid traverses per shift.

• Standard 10 Inches of Z: Perfect for tall parts, pod work, fixture work, prototyping, or 3D parts.

• Standard Multizone Table: Automatically activates the correct vacuum zones for your different sheet or part sizes.

• Choice of 8 Automatic Pop-Up-Pins or Steel Pop Up Rails: Both are square and referenceable for parts or sheets.

• Pre-Wired and Pre-Machined: Ready for an automatic material pusher sweeper device or integrated automatic material conveyor to be added or retrofitted in the field.

Detailed Specifications of the Anderson Selexx Plus

Explore the comprehensive tables below to understand the capabilities of the Anderson Selexx Plus. These tables provide a clear, easy-to-understand overview of the key specifications, features, and additional options of our high-performance CNC machine. From a variety of table sizes to aggregate capability, automatic vacuum zones to pre-wiring for additional features, every aspect of the Selexx Plus is designed with your needs in mind. Explore the tables to understand how the Selexx Plus can elevate your CNC capabilities.

| Basic Configuration | Selexx 48 TC+D | Selexx 510 TC+D | Selexx 512 TC+D |

|---|---|---|---|

| No. of vacuum zones | 2 | 3 | 4 |

| Table size X | 2500 mm (98.4") | 3100 mm (122") | 3750 mm (147") |

| Table size Y | 1250 mm (49") | 1550 mm (61") | |

| Stroke of X-axis | 2630 mm (103.5") | 3180 mm (125") | 3880 mm (152") |

| Stroke of Y-axis | 1720 mm (67.7") | 1835 mm (72") | |

| Stroke of Z-axis | 250 mm (9.84") | ||

| Rapid travel Speed in X | 80 meters/min (3,149"/min) | ||

| Rapid travel Speed in Y | 60 meters/min (2,362"/min) | ||

| Rapid travel Speed in Z | 20 meters/min (787"/min) | ||

| Maximum Rapid Traverse | 100 meters/min (3,937"/min) | ||

| Spindle Power | 12 HP / 18 HP | ||

| Max. Speed (rpm) | 22,000 | ||

| Clamping system | HSK-63 | ||

| Ride along tool changer | 8 / 10 | ||

| Boring block | 5+5 or 10+7 | ||

| Vacuum pump | 10/25/40 HP | ||

| Controller | FANUC 0i | ||

| Dimensions: A | 3,595 mm (142") | 4700 mm (185") | 4,782 mm (188") |

| B | 4,000 mm (157") | 4,250 mm (167") | |

| C | 2,300 mm (90.5") | ||

| Weight | 3,200 Kg (7,055 lbs.) | 4,600 Kg (10,132 lbs.) | 5,000 Kg (11,000 lbs.) |

| OPTIONAL | |||

| Reverse Air Flow | optional | ||

| Bar-Code Reader | optional | ||

| C-axis | optional | ||

| Offload Pusher/Sweeper | optional | ||

| Automatic Loading | optional | ||

| CNC Label Placement | optional | ||

Request a Quote

Enter your email and submit a request for a quote for the

Highland Article #: SELEXX Series

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.