Cantek EM12 End Matcher

Cantek EM12 End Matcher is backordered and will ship as soon as it is back in stock.

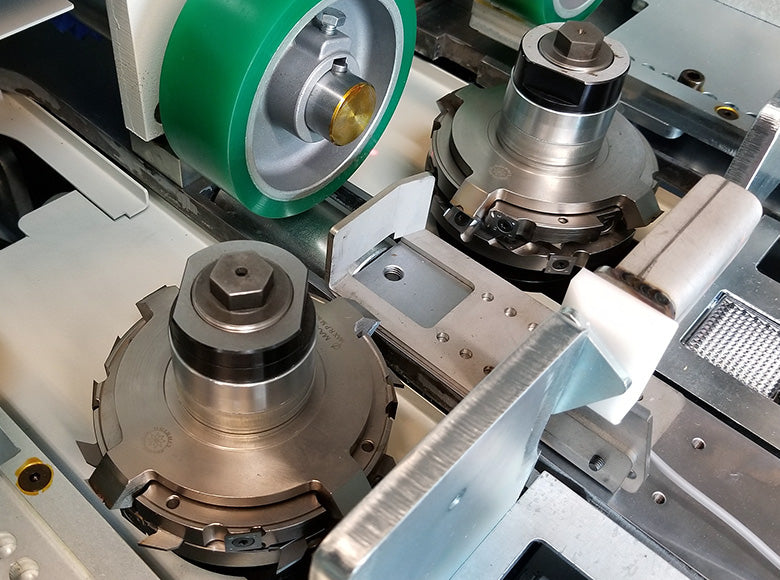

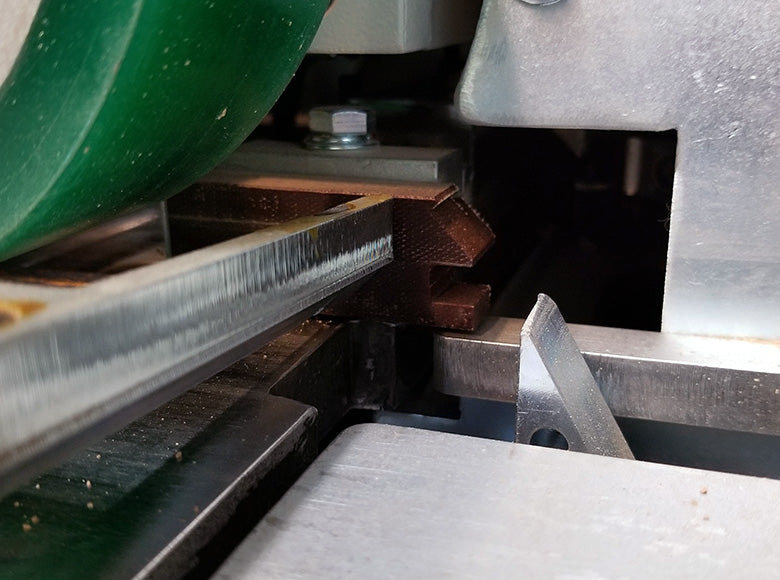

The Cantek EM12 End Matcher is specially designed for machining tongue and groove (with or without bevels) on hardwood flooring and wall/ceiling paneling up to 12in wide. Its compact design with continuous through feed system allows for maximum output in a small space. Equipped with a user-friendly touch screen interface allow for simple operation with excellent performance and error diagnostics. The dual counter-rotating cutterheads produce both the tongue and groove simultaneously ensuring a perfect match. The anti-tear-out blocks and counter rotation of the heads ensure optimum cut quality without chipping or blowout. The insert style segmented cutterheads can be adjusted according to your desired tongue / groove thickness and can perform a micro-bevel or not. The variable speed infeed conveyor, variable feed speed, and variable cross-cutting speed allow the operator full control according to the type and size of material being run. The innovative clamps allow for simultaneous top and side clamping to ensure pieces are perfectly square for consistent end matching results.

For added productivity the EM12 End Matcher can be installed in-line with the Cantek CFS100 Automatic Defect Cutoff Chop Saw to perform defecting and end matching in a single line. This greatly reduces the handling while increasing output with defect free flooring or paneling.

Key Advantages

• Variable speed through-feed system is controlled by frequency inverter

• Powered top urethane rolls and spring-loaded bed rollers feed the material into position for processing

• Pneumatic side pressure system ensures the material is held square against the fence

• Capable of processing material as short as 12” to an unlimited length

• Cutterheads are stacked and fully adjustable with replaceable and rotatable insert knives

• Cutterheads are equipped with removable micro bevel insert cutter section for bevel or square flooring / paneling

• 118in powered infeed table with angled rolls ensure material is fed up against the infeed fence

• 87in outfeed slide table allows board to slide out of the way while the next board comes through to be processed resulting in continuous production

• Chrome table ensures maximum wear resistance

• Complete safety and noise reduction enclosure

• Added feature of inverter-controlled infeed conveyor allows you to slow the infeed speed when dealing with heavy boards

| Width | 1.6in~12in |

| Thickness | 0.4in~1.38in |

| Min. Length | 12in |

| Max. Length | UNLIMITED |

| Feed Speed – max. | 295 FPM |

| Cutting Speed – approx. throughput | 77 FPM (Based on 6.5ft board) |

| Powered Infeed Table – Std. | 173in (14.4ft) long – longer optional |

| Outfeed Table – Std. | 86.6in (7.2ft long – longer optional |

| Cutterheads | 10Hp x 2 |

| Feed System | 1 Hp |

| Cutter Drive | 1/2 Hp |

| Power | 230, 460 or 575/3/60 |

| Control Voltage | 24 VDC |

| Connected Load | 21.5HP |

| Full load amperage (FLA) | 230/3/60 – 50.4 Amps |

| 460/3/60 – 25.20 Amps | |

| Clamping | Top & Side |

| Spindle Dia. | 40mm |

| Dust Collection Outlet | 6in diameter |

| Compressed Air Requirements | 85PSI – approx. 12 CFM |

| Machine Dimensions (LxWxH) | 91in x 51.5in x 63in |

| Machine Weight | 2530 lbs. |

Highland Article #: EM-12

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.