Hendrick HC6 Series Horizontal Panel Saw

Request a Quote

Enter your email and submit a request for a quote for the

Hendrick HC6 Series Horizontal Panel Saw is backordered and will ship as soon as it is back in stock.

Computer Precision with Power and Control

Heavy-duty production requires top-of-the-line equipment – maximize your power while minimizing errors with the HC6 series panel and beam saw. Precision is built into every inch, with pneumatic material grippers for automatically loading and securing your material, a split hold-down beam, and dual fully automatic side aligners.

Accuracy is ensured with rack and pinion indexing between cuts, AC closed-loop servo, the digital magnetic scale read back, as well as a robust industrial PC controller with on-board optimization & diagnostics software. Get incredible power with the HC6’s 6” cut depth and full 25 HP main blade motor. When you have heavy-duty production needs and no room for errors, the HC6 series is up to the task.

The HC6 Cuts Into

|

|

|

|

| Corrugated | Plastic | Wood |

HC6 Standard Features

• Standard Lengths of Cut: 5′, 8′, 10′ & 12’

• 20 HP Main Blade Motor for HC4 & 25 HP Main Blade Motor for HC6

• Variable Saw Carriage Speed with High Speed Return

• Separate Scoring Blade for Chip Free Cutting

• Manual or Fully Automatic Cutting with Easy-To-Use Programmable Controller

• Solid Surface Allows for Cutting of Small Parts

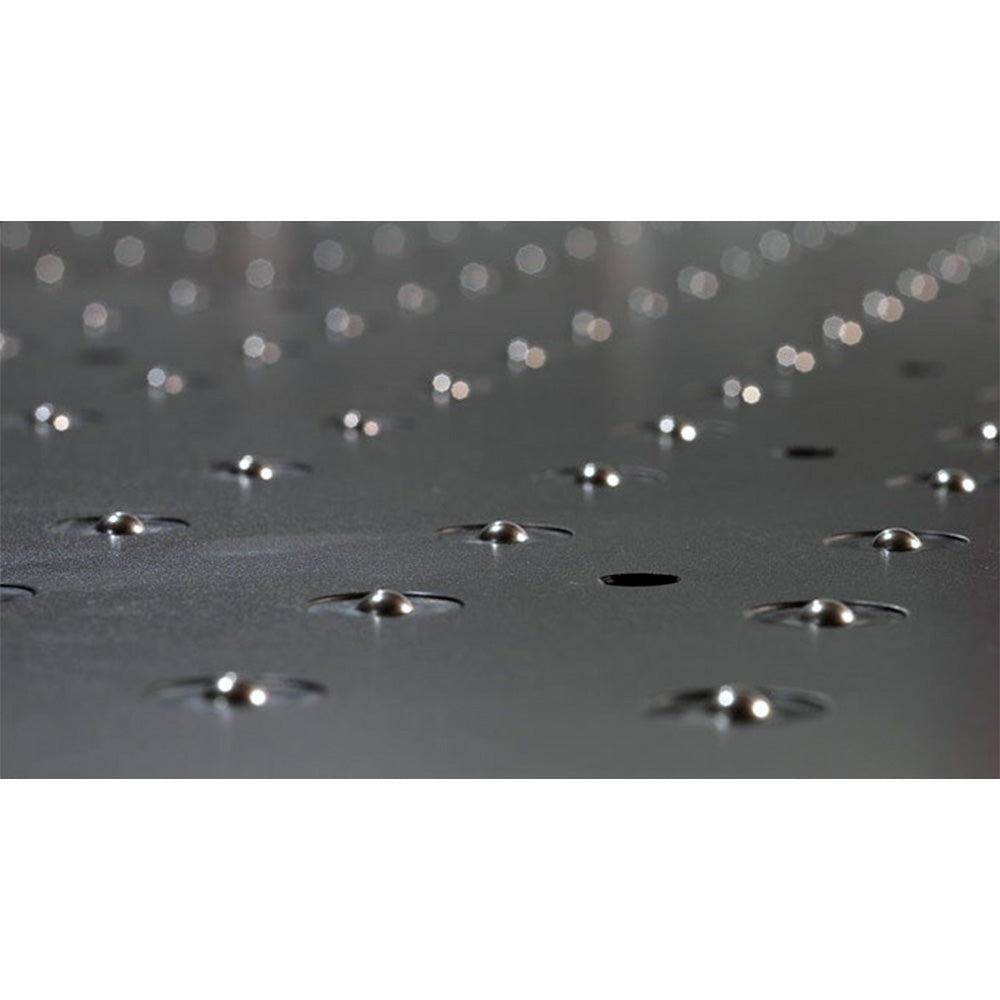

• Air Floatation Tables

• PC Machine Controller with On Board Optimization Software

Greater Power and Precision

Indexing & Grippers Ensure Part Accuracy

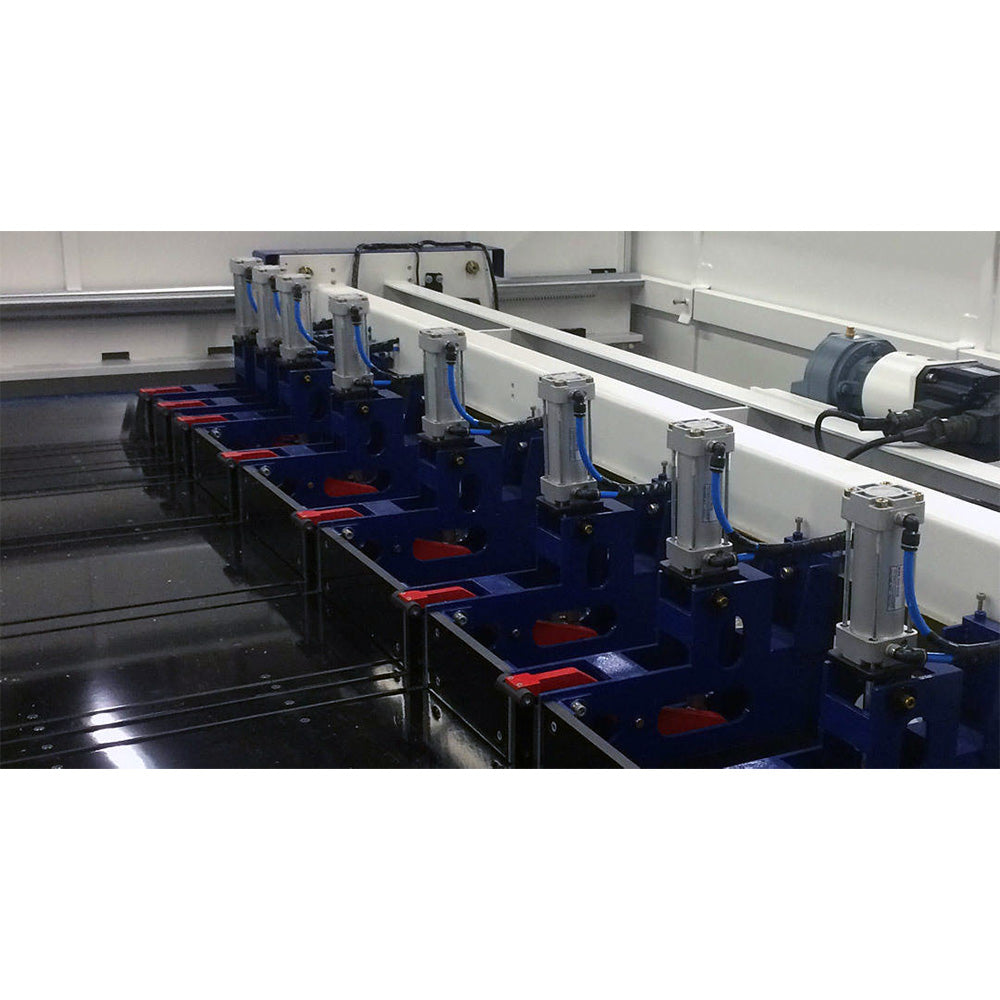

Automatically load heavy material and stacked sheets onto the solid phenolic rear table for processing. Achieve faster cycling speeds with grippers holding the material for cutting and indexing. Solid pusher plates between the grippers allow cross and parallel cutting of narrow strips. Maximize accurate positioning and cutting with a closed loop AC servo system featuring precision ground rack and pinion, AC servo resolver, and a magnetic scale.

Easy Loading and Unloading

Lighten the load for your operators with air floatation tables for easy material handling.

Adjustable Pressure Regulators

Maintain control with quick adjustment of individual devices like material grippers, pressure beam, and material side aligners, all from simple front-mounted pressure regulators.

PC Controller with Onboard Optimization

• IPC controller running Windows 7 with a LAN interface, CD ROM, solid state hard drive storage (SSD) and high speed USB-II ports.

• 19” full color flat screen with animated cut pattern graphics.

• On-board Material Optimization Software to optimize material waste. Provides plan-to-execution from optimization mode.

• On-board diagnostics show the status of all machine I/O devices to minimize downtime. Diagnostics also provide “how to” solutions that point to problems and provide corrective actions.

• Ammeter on front panel to monitor saw blade load. On screen diagnostics on the controller for easy troubleshooting.

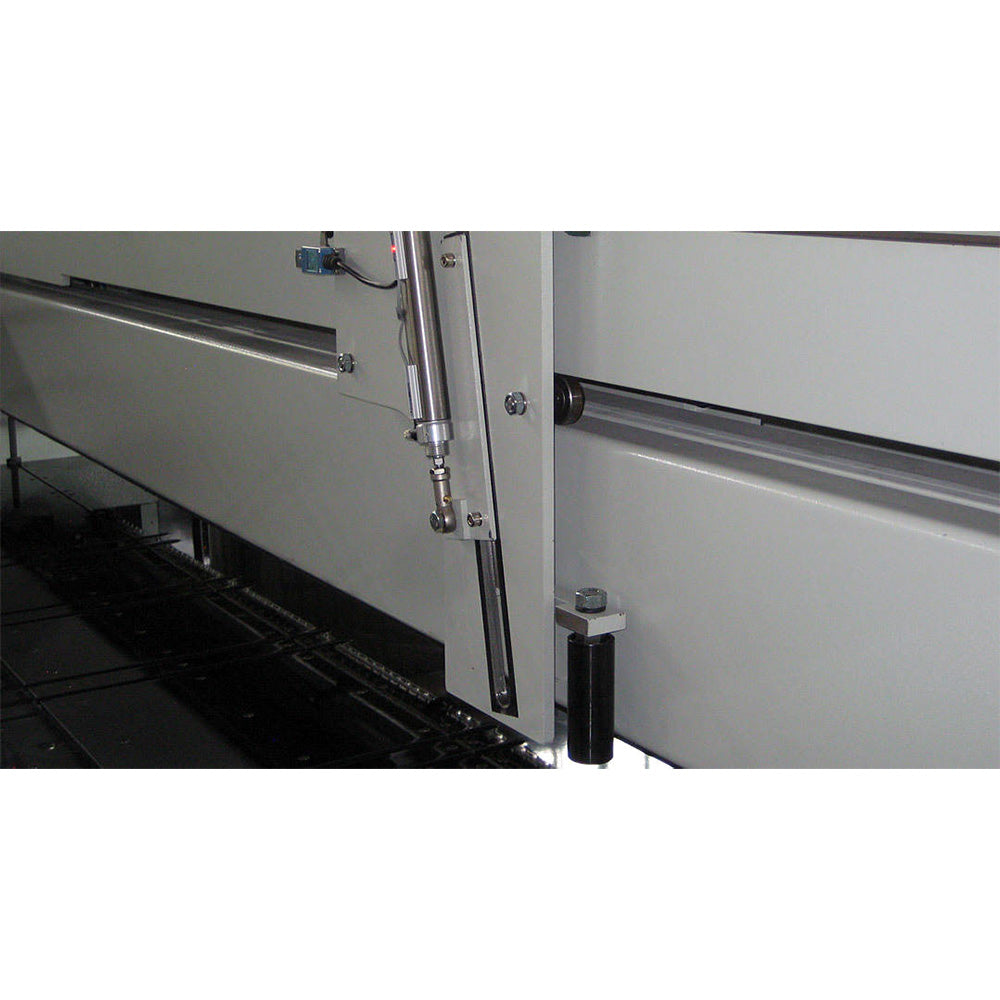

Dual Material Side Aligners

Ensure perfectly square cuts and minimize stroke and cycle times with an encoder that automatically positions the dual side aligners to the width of the material being cut before it’s activated. Each side aligner works independently to apply pressure to hold your material against the squaring fences on both the front and back side of the saw blade as the pusher approaches the cut line.

HC6 Optional Features

• Spray Mist Blade Coolant

• Custom Table Configurations

• HMI Touch Screen Controller

• Variable Speed Saw Blade RPM via AC Inverter

• Quick Change Saw Blade Arbor

• Auto Saw Blade Height Adjustment

Highland Article #:

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.