Leadermac Hypermac Moulder Series

Request a Quote

Enter your email and submit a request for a quote for the Leadermac Hypermac Moulder Series

Heavy–duty non jointed moulder, for the most complex mouldings, or most difficult material types, wet or dry.

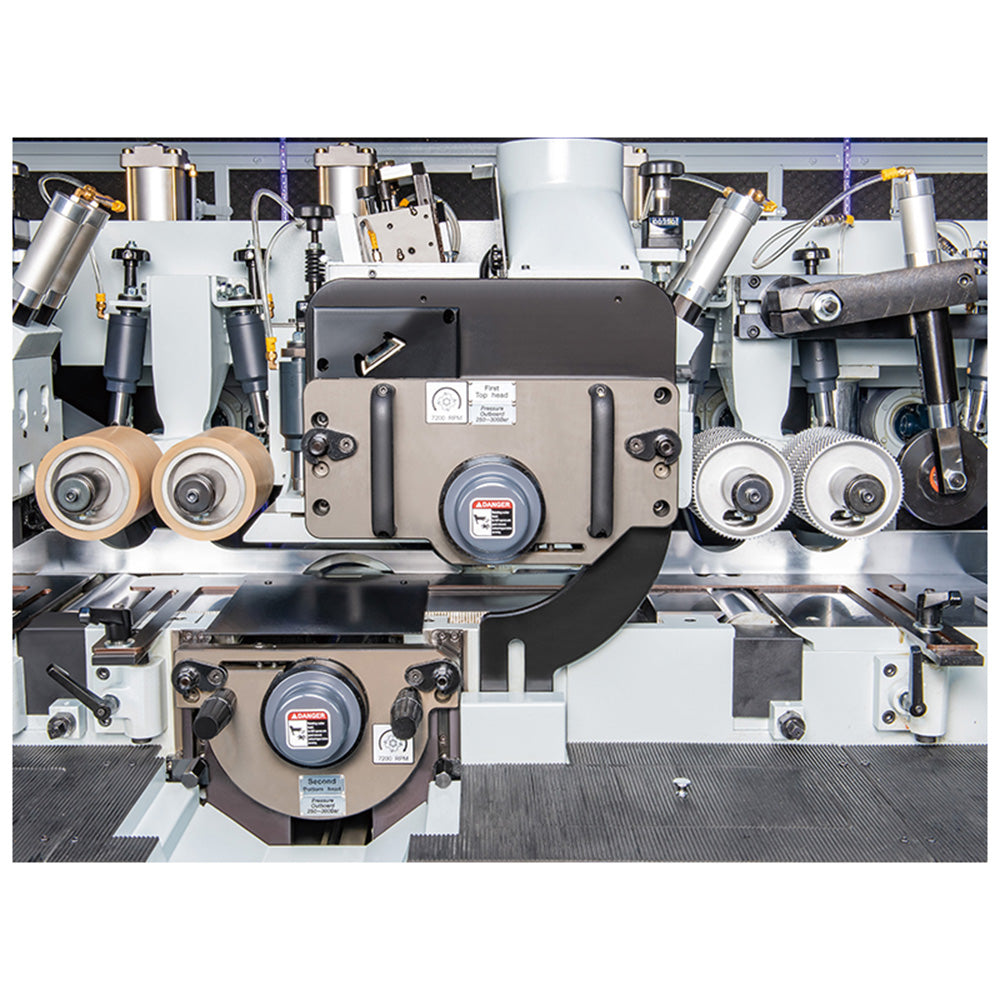

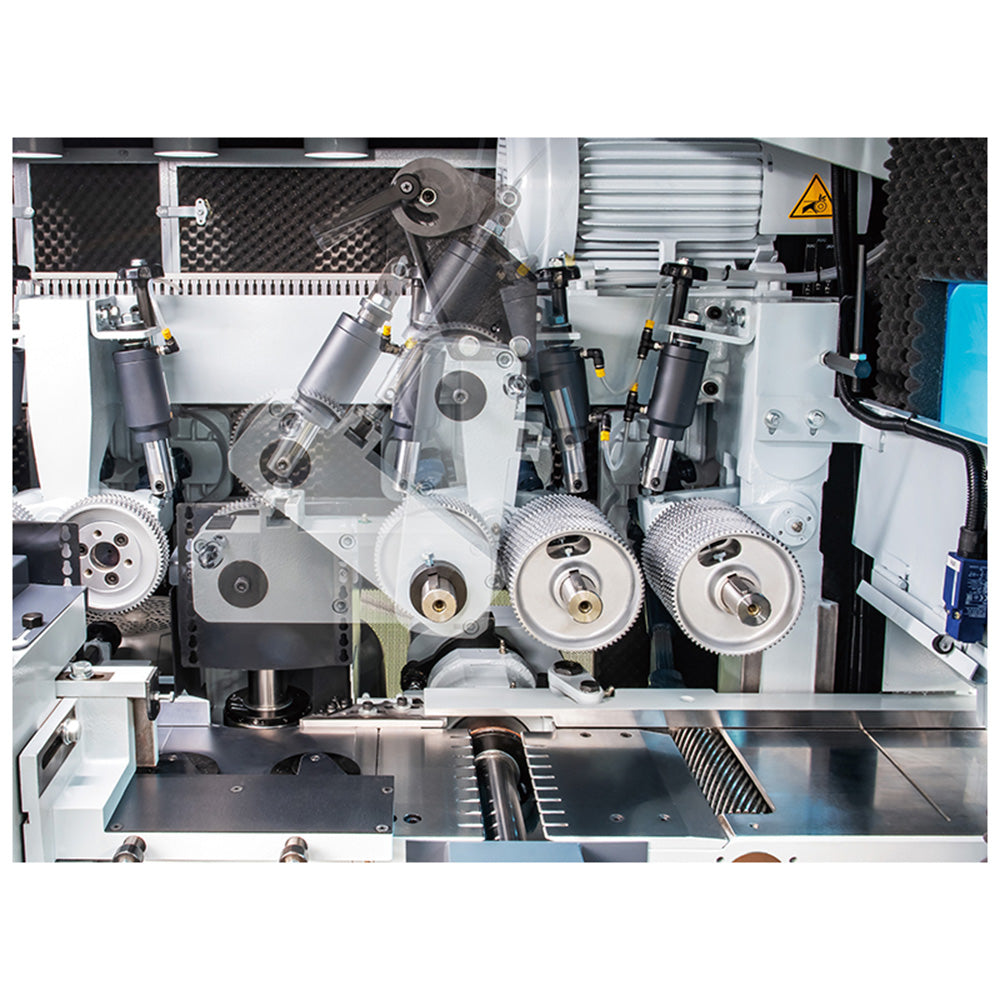

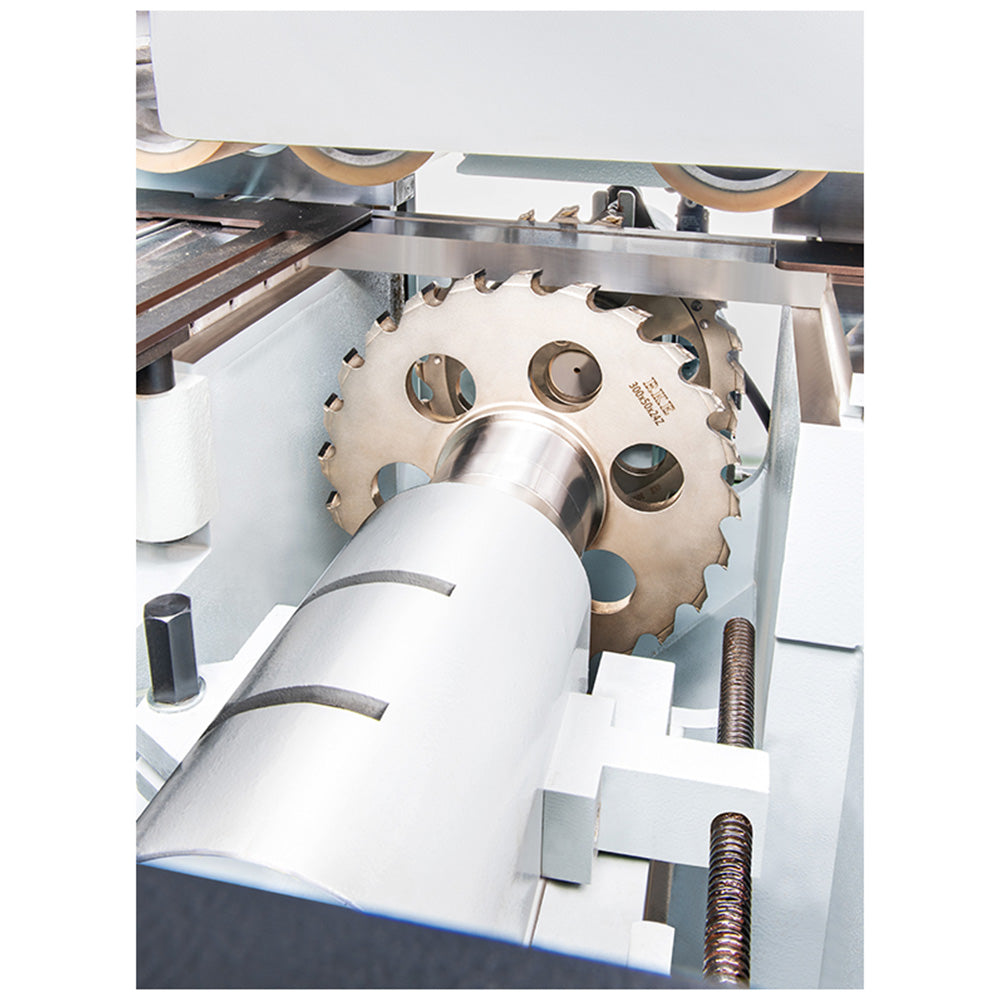

The Leadermac Hypermac Moulder Series has been designed to ensure a high–quality finish, with a range of options to meet your particular needs. The Hypermac moulder is commonly brought in with 8000 rpm spindles, allowing you to run 33% faster than a 6000 rpm machine, producing an excellent quality finish. Its larger cutterhead swing allows for heavier and deeper cuts for the most complex of mouldings. It is a tight coupled machine to ensure total control and smooth feeding of the workpiece as it passes thru. Many powerful features come standard with the Hypermac ensuring fast and repeatable setups with reduced changeover time, allowing you to meet your production requirements day in and day out.

Key Advantages

• Heavy-duty cast iron frame provides superior vibration damping, which produces superiorly finished parts and promotes long bearing & machine life

• Tightly coupled machine ensures smooth and consistent feeding to assist in producing high-quality finish

• All tables and fences hard chromed with approximately 0.012″-0014″ thick hard chrome, which ensures maximum longevity

• Comes with more top driven and bottom full width driven feed rolls than other moulders of its size

• Bottom bed rolls can be adjusted up and down with a simple adjustment from the front of the machine.

• 8000 RPM spindles each with (4) ABEC 7 precision bearings per spindle which provides smooth surface finish results

• Larger cutterhead swing allows for deeper and more complex profiles.

• Pneumatic side holdover provides consistent side pressure to the fence

• Pneumatic hold down pressure to all top feed rolls provides consistent and repeatable pressure

• Pneumatic chip breakers ensuring consistent pressure

• Full width driven infeed & outfeed bed rolls

• Short stock feed roll station

• Machine comes standard with Easyset touch screen control setworks (other setworks systems available to increase automation)

• Set up controls mounted on pendant with 12′ cord to allow the operator to carry in front of the machine during setup.

• Axial adjustment of last bottom head from front of machine

• Heavy-duty pneumatic, automatic and programmable table lubrication system

• Centralized grease lubrication system

• Safety sound enclosure is standard

• Pneumatic pressure to chip breakers, holdovers, and top feed rolls

Options

• Variable frequency drives for spindles: allow RPM of spindles to be varied and act as a fully electronic braking system.

• Split hold down pressure shoe.

• Anti-kickback fingers for ripping operations.

• Rip bed plates / special pressure shoe for ripping operations.

• Universal spindle.

• 7200 or 8000 RPM spindles for increase feed speeds.

• 12″, 13″, or 15.75″ wide machines with outboard bearings.

• Grooved bed machines for short part feeding.

• Telescopic top feed roll unit opposite left vertical side head.

• 8″ diameter feed rolls in lieu of 5.5″/40mm standard rolls.

• 2/2 Heavy duty feed system for more challenging products.

• Increased Axial adjustment to vertical spindles.

• Tilting vertical spindles.

• Smartset 100 Setworks System with touch screen control, memory system, and motorized positioning for near side and top head, utilizing ball screw and rotary encoder for true accurate and repeatable positioning.

• Proset Setworks system, with link to the grinding room, allowing the building of tool, profile libraries. Transfer of measurements after grinding via a video measurement stand to the PC to update all profiles. This system is designed to ensure the fastest of changeovers, allowing easy management of larger numbers of tools, product profiles, and changeovers as required.

• Router spindles for special profiling.

• Automatic width setting with measuring probe for random width material.

• Multiple ripsaw spindle with sleeve.

• Vertical spindle slicing/ripping system.

• Special requirements on request.

Highland Article #: LMC623H

-

Working Widths

-

Working Thickness

-

Number of Spindles

-

Spindle RPM

-

Standard Feed Speed

-

Minimum Part Length

-

Axial Adjustment of Veritcal Spindles

-

Axial Adjustment of Horizontal Spindles

-

Infeed Bed Length

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.