Cantek ECT Series Double End Tenoners

Cantek ECT Series Double End Tenoners is backordered and will ship as soon as it is back in stock.

Production double end tenoner series for doors, windows, and more.

The Cantek ECT Series Double End Tenoners are robustly built for the most demanding applications. They are available with up to (8) spindles (4-per side) and come in widths from 51" to 141". These double end tenoners are ideal for door, furniture, & window production and more. The ECT series can be customized for your specific needs with a wide range of processing units and features. The ECT series is available as a stand-alone solution or can be purchased in a line for processing all four sides of a

workpiece automatically.

Key Advantages

• Industrial cast iron machine base for superior vibration damping resulting in optimum cut quality and machine life

• Motorized width adjustment

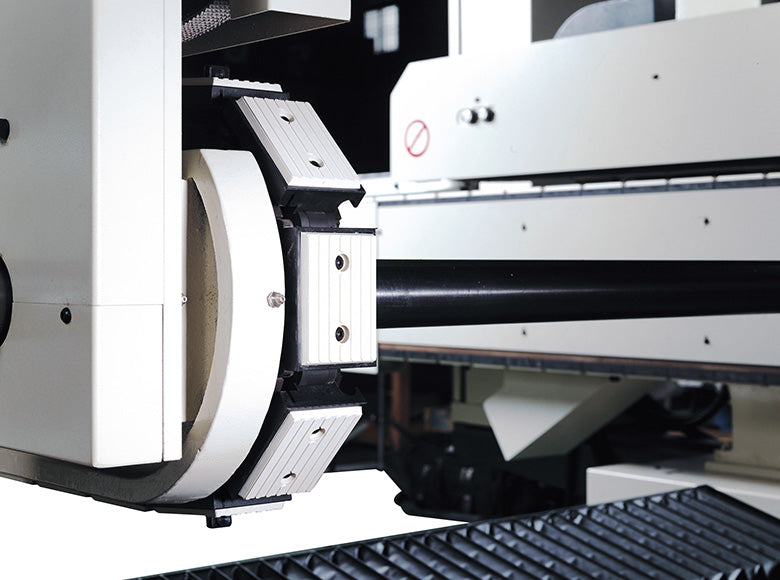

• Precision chain track assemblies with manually retractable stop dogs to ensure perfect squareness

• Variable feed speed

• Safety equipment includes enclosed cabinet with safety interlocks on access doors

• Automatic braking of saw blades and moulding heads

• Digital readout for thickness adjustment

• Feed conveyor is equipped with needle bearings to increase wear-resistance.

• Choice of rubber or phenolic surface

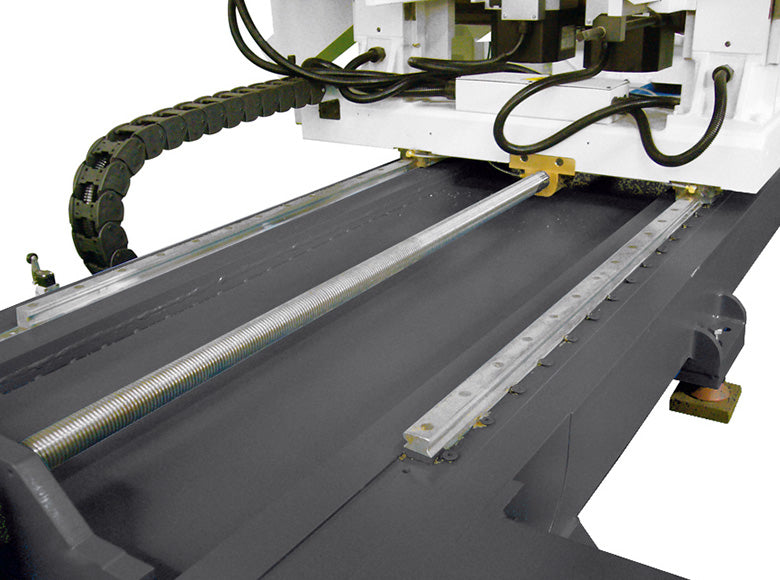

• The movable side of the double end tenoner is mounted on precision linear guideways to ensure accuracy and smooth movement

• Mechanical digital readouts for accurate positioning of each working unit

• Optional HSK and quick set tooling

Specifications

| ECT-86S | ECT-66S | ECT-46S | |

|---|---|---|---|

| Max. working width | 2600 (3000 / 3600) mm | 2000 mm | 1300 mm |

| Min. working width | 210 mm | 210 mm | 210 mm |

| Max. working thickness | 120 mm | 120 mm | 120 mm |

| Feed Chain Track | |||

| Motor horsepower | 2 (3/5) HP | 2 (3/5) HP | 2 (3/5) HP |

| Feed speed | 5-25 m/min | 5-25 m/min | 5-25 m/min |

| Distance between dogs | 400 (300 / 200) mm | 400 (300 / 200) mm | 400 (300 / 200) mm |

| Movable Side Shifting System | |||

| Motor horsepower | 1 HP | 1 HP | 1 HP |

| Feed speed | 2 m/min | 2 m/min | 2 m/min |

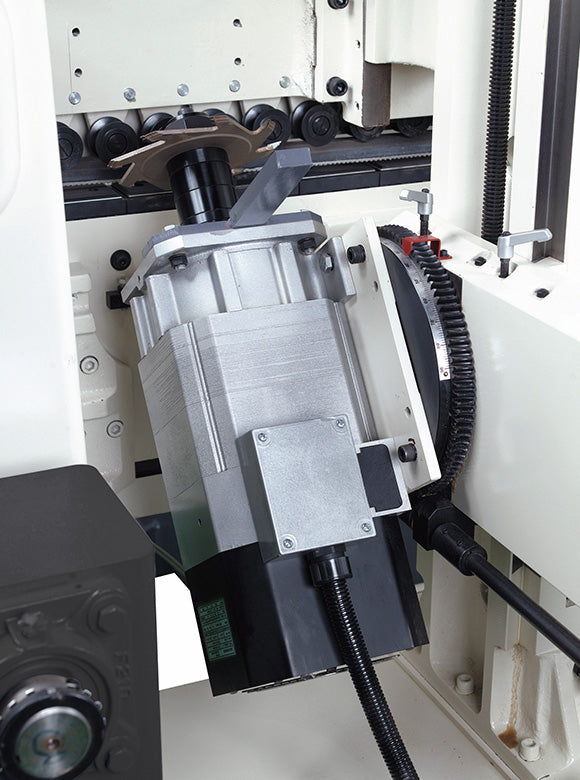

| Scoring Saw System | |||

| Motor horsepower | 2 (3 / 5 / 7.5) HP | 2 (3 / 5 / 7.5) HP | 2 (3 / 5 / 7.5) HP |

| Spindle speed | 3450 rpm (60Hz) | 3450 rpm (60Hz) | 3450 rpm (60Hz) |

| Spindle diameter | 25.4(30) mm | 25.4(30) mm | 25.4 (30) mm |

| Sawblade diameter | 120-305 mm | 120-305 mm | 120-305 mm |

| Main Saw System | |||

| Motor horsepower | 5 (7.5/10) HP | 5 (7.5/10) HP | 5 (7.5/10) HP |

| Spindle speed | 3450 rpm (60Hz) | 3450 rpm (60Hz) | 3450 rpm (60Hz) |

| Spindle diameter | 25.4 (30) mm | 25.4 (30) mm | 25.4 (30) mm |

| Sawblade diameter | 205-355 mm | 205-355 mm | 205-355 mm |

| Moulding System | |||

| Motor horse power | 5 (7.5/10) HP | 5 (7.5/10) HP | 5 (7.5/10) HP |

| Spindle speed | 3000 / 8000 rpm | 3000 / 8000 rpm | 3000 / 8000 rpm |

| Spindle diameter | 40 mm | 40 mm | 40 mm |

| Cutter diameter | 180 - 210 mm | 180 - 210 mm | 180 - 210 mm |

| Weight & Dimensions | |||

| N.W. | 4350 kg | 3900 kg | 3500 kg |

| Machine size (mm) | 4560 x 2360 x 1470 mm | 3960 x 3260 x 1470 mm | 3360 x 3260 x 1470 mm |

Request a Quote

Enter your email and submit a request for a quote for the

Highland Article #: ECT-66S

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.