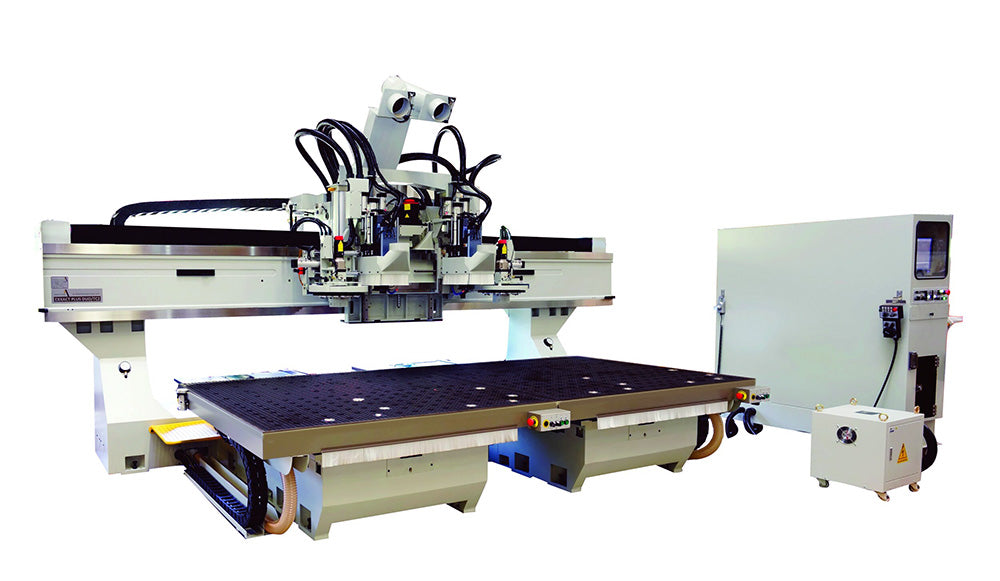

EXXACT Series Single or Twin Table 3 and 4 Axis CNC Machine

EXXACT Series Single or Twin Table 3 and 4 Axis CNC Machine is backordered and will ship as soon as it is back in stock.

Introducing the EXXACT Series Moving Table 3-Axis Machining Centers

The EXXACT Series Moving Table 3-axis machining centers are redefining the standards of CNC accuracy and machining performance. With their unparalleled precision and robust design, they offer an unmatched level of efficiency in the industry. Experience the revolution in CNC machining with the EXXACT Series, where superior performance meets cutting-edge technology.

Superior Accuracy and Unrivalled Efficiency

Equipped with a sturdy base and castings, and complemented by a high-precision Servo System, the EXXACT machining centers serve as an ideal platform for handling a diverse array of materials with ease and efficiency.

Key Features

• Versatile Material Processing - Ideal for wood, MDF, plywood, plastic, aluminum, and composite materials.

• Anderson Fixed Bridge and Moving Table Design - Ensures effortless machine access.

• Webbed Steel Substructure - Remains smooth and rigid while cutting in X, Y, and Z-axis.

• Ethernet Options - Enables remote technical support.

• Optional C-Axis - Enhances your machining capabilities.

• Workpiece Holding Flexibility - Optional clamping, grid, or manifold vacuum systems.

Detailed Specifications of the EXXACT Series

Explore the comprehensive tables below to understand the capabilities of the EXXACT Series Moving Table 3-axis machining centers. These tables provide a clear, easy-to-understand overview of the key specifications, features, and additional options of our high-performance CNC machine. From material versatility to the unique Anderson fixed bridge and moving table design, every aspect of the EXXACT Series is designed with your needs in mind. Explore the tables to understand how the EXXACT Series can elevate your machining capabilities.

| Basic Configuration | EXXACT |

| No. of tables | 1 |

| No. of vacuum zones per table | 1 or 2 |

| Table size X | 3700mm (146 in) |

| Table size Y | 1600 mm (63 in) |

| Stroke of X-axis | 4400 mm (174 in) |

| Stroke of Y-axis | 1775 mm (70 in) |

| Stroke of Z-axis | 350 mm (14 in) |

| Rapid travel Speed in X | 80 M/min (3150"/min.) |

| Rapid travel Speed in Y | 80 M/min (3150"/min.) |

| Rapid travel Speed in Z | 30 M/min (1181"/min.) |

| Spindle Data | |

| Power | 18HP/24HP |

| Max. Speed (rpm) | 24000 |

| Clamping system | HSK-63F |

| Ride along tool changer | 10/12 |

| Boring block | 5+5 or 10+7 |

| Vacuum pump | 10/25/40 HP |

| Controller | FANUC 0i |

| Dimensions: Floor Area | 6000 x 3375 mm (236 x 133 in) |

| Height | 2800 mm (110 in) |

| Weight | 9300 kg (20,500 lbs.) |

| OPTIONAL | |

| Vector Spindle HSK 63-E | |

| Reverse Air Flow | |

| Bar-Code Reader | |

| C-axis | |

| Gantry Offload Pusher | |

| Automatic Loading | |

Request a Quote

Enter your email and submit a request for a quote for the

Highland Article #: EXXACT Series

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.