RFS Protech PT7 Veneer Former

RFS Protech PT7 Veneer Former is backordered and will ship as soon as it is back in stock.

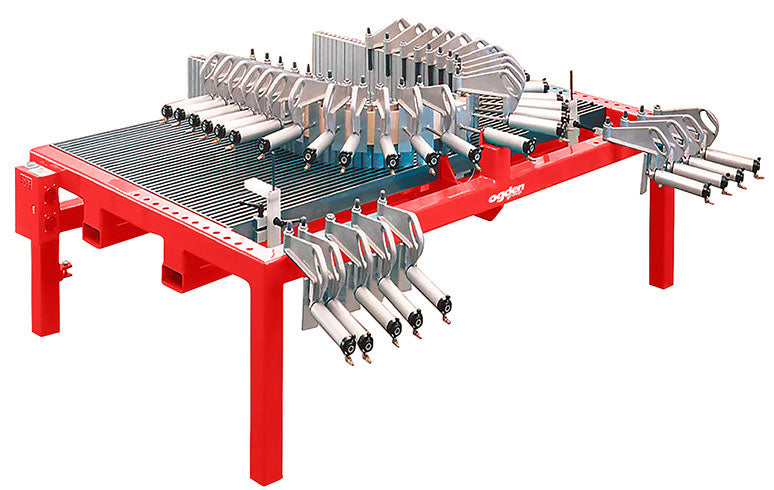

The RFS Protech PT7 Radius Former uses a series of machined rails supporting dual sets of heavy aluminum arms, which are adjusted to define the pattern to be fabricated.

The Veneer Slats are clamped to the form arms with a series of 32 specially designed Air cylinders, which use pneumatic air pressure up to 120 psi and are connected to the clamp via quick disconnect.

The RFS Protech PT7 can be used as a cold press or equipped with an optional set of thermostatically controlled heat bands. Depending on the size of the component and adhesive used, the heat bands can cure the assembly in as little as 20 minutes.

ABOUT

The PT series of Radial Forming Machines was developed as an economical alternative method to easily and accurately fabricate curved components such as arched headers and radiused moldings for windows and doors, furniture parts, etc. These machines are designed to fit the needs of small and large companies. The PT Radial Forming machines can produce a wide range of shapes without the use of forms or templates. The patented, ruggedly built machines feature welded steel frame construction and quality components for a long and productive life. The machine can be used as a cold press or with optional heat bands or a with High Frequency Generator to cure the glue lines. The machines can be built with manual adjustable forms or fully CNC forms which move into position via computer control touch screen.

AVAILABLE OPTIONS

Straight leg table extensions

Air pressure boosters

Conduction heat band curing

Variable clamp capacities

Casing attachment

Request a Quote

Enter your email and submit a request for a quote for the

Highland Article #: Radius PT7

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.